Home » Horizontal centrifugal pumps » CMO-N

CMO-N

Horizontal centrifugal pumps with mechanical seal

CLOSE COUPLED

The centrifugal monobloc range CMO-N, has been designed in order to obtain the best performances with a reduced cost. Easy to handle, the pumps of this range are strong, compact construction, produced in their components with high thickness to give a product with the maximum reliability.

Material of Construction

Suitable to transfer acid and basic solutions, the wet ends, are produced in thermoplastics (PP-PVDF) and O-ring in the proper elastomer material (EPDM-FPM-FEP-FFKM). Different mechanical seal solutions are available: from the lip seal to primary label seals (internal, external and double flushed) in standard version with faces in Silicon Carbide (SiC-SiC) and bellow elastomer (FPM-EPDM). The impellers installed are generally semi-open, but they are available in the closed version for hot liquids and without solids in suspension.

Accessories

• Draining hole

• Self-priming tank

• Pressurised tank for mechanical flushing

Download the catalog and the technical sheet complete with technical drawing with overall dimensions

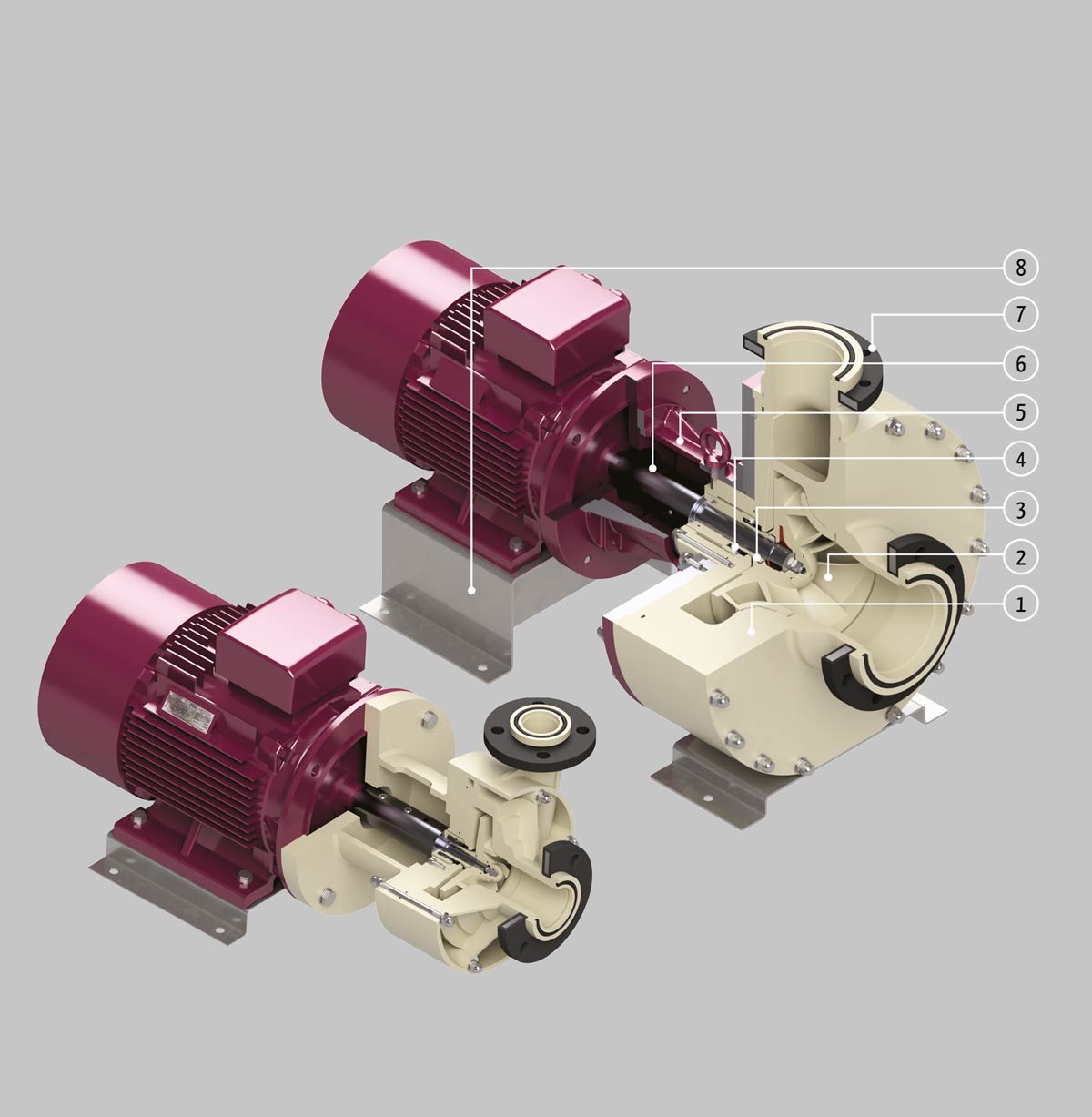

Main Components

Casing made of extra-thick PP or PVDF, manufactured using mechanical machining processes for 65-125 and 65-160. For pump models 25-125, 32-125, 40-130, 40-160 and 50-160, the part is injection moulded.

Centrifugal impeller made of PP or PVDF; semi-open model for particle-loaded fluids and closed for pumping high-temperature solutions. Axial self-balancing guaranteed by rear counter-blades.

Shaft sleeve in PP or PVDF. Fully covering the part of steel shaft in contact with the process liquid and manufactured as a one-piece component. It rotates integrally with the impeller but is independent from it.

Standardized mechanical seal, selected according to plant requirements and process requirements.

Intermediate adaptor of a strong design in thermoplastic material from 25-125 to 65-160 and in cast iron from 32-200 to 125-250. A unique piece designed to space electric motor from head pump.

Balanced shaft made of 42CrMo4 Carbon steel (with special alloy on demand), oversized to support torsional and radial forces. Precision machined from solid bar stock.

Loose flanges in glass-reinforced PP, strengthened internally with a steel core.

Base plate in SS316 Stainless steel.

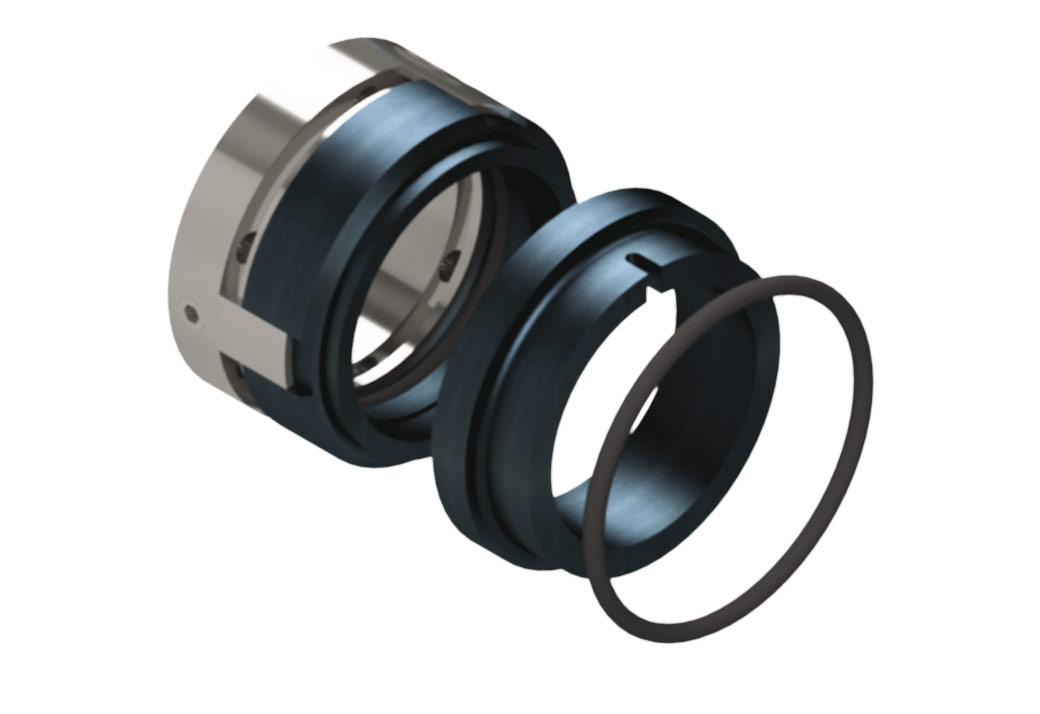

Mechanical seals

Elastomeric bellows seal

Mechanical seal for moderately corrosive, clean and not excessively hot liquids. Static and rotating rings in SiC, spring and armour in SS316 not in contact with the process liquid, elastomeric bellows in EPDM or FPM. Available in the external (B6E – B6EC), internal (B6I – B6IC – B6IH) and double-flushed (B6EDF – B6EDFC) types.

PTFE bellows seal

Mechanical seal for highly corrosive fluids and high temperatures. Static and rotating rings in three different combinations (SiC-SiC, SiC-Al2O3, Al2O3-PTFE-C), PTFE bellows, spring and armour in SS316 not in contact with the pumped liquid. Available in external (JRS – JRS1 – JRA) and double-flushed (JR2S – JR2S1 – JT2P – JR2A) types.

Seal with elastomeric O-ring

Mechanical seal for moderately corrosive, clean and not excessively hot liquids. Static and rotating rings in two different combinations (SiC-SiC, Carbon-graphite-SiC), spring and armour in Hastelloy C276, O-ring in EPDM o FPM. Available in the internal (UMG – UMS) and double-flushed (UM2G – UM2S) types.

application fields